In 1999 I began what has turned out to be a large transition. I retired rather abruptly from teaching and passed through a health crisis (a modest one) and began a recovery process which took a while. I found I had the time and inclination to think about my situation and the future. It was clear that I could not go on as I had been . I began a process which is still on-going – rethinking everything. Instead of winging it, I began to redesign my making process. Clay body, clay preparation, other ways to make slabs, slips, glazes, firing, the kiln, everything. Starting in 2000 every pot has a number derived from the date when it was made. I make notes about each pot, keeping track of anything that I might wish to remember.

In an effort to reduce or eliminate hand kneading the clay, I experimented with using the clay directly from my clay mixing machine (a pug mill). I was beset with small seams in the clay which could be eliminated by hand kneading, but what if I had a bad anything (foot, ankle, knee, hip, back, shoulder, elbow, wrist – even hand!) – how could I do the kneading? I thought that pressure might eliminate the seams and I built a series of presses in the hopes of fusing the seams under pressure. It has been 90% successful. But in the process, I needed to keep the clay from sticking to the press. I used a sheet of plastic above and below the clay. After the squashing, I peeled the plastic off and it left a very surprising surface. It varied depending on the clay and the thickness of the plastic. The plastic always developed some wrinkles. The resulting surface is more like concrete that has not been trowelled, or a scarred rock surface. I continue to experiment, but this development formed the basis for the current pots: a squashed, double thick slab that is wire cut into two matching pieces, with patterns (new) used to construct more complicated shapes including bowls.

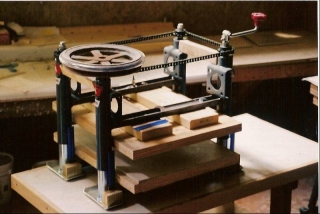

Clay squasher Capacity 18″ x 24″

The new texture

Vase 12″ high 2003